Smart Warehousing

By , 14 July 2021 18:19

How Cloud WMS Supports Smart Warehousing and Industry 4.0

By helping distributors and manufacturers tackle their most complex pain points, cloud WMS provides new ways of improving efficiency, optimizing labor, enhancing productivity, mitigating risk, and reducing errors.

A series of interconnected processes focused on reducing the time it takes to get an order from the shelf to the loading dock, the “smart warehouse” is getting a lot of attention right now. Grappling with challenges like the trade wars, the massive uptick in e-commerce, the persistent labor shortage, and the need to cut costs, organizations need modern solutions that optimize

their operations.

They’re not getting what they need from their existing systems. That’s because many of them still depend on old legacy “green screen” systems to run their operations. These platforms continue to do the bare minimum that they did 10 or 20 years ago, but they don’t help distributors leverage smart warehousing, nor do they propel manufacturers in the direction of Industry 4.0.

The Warehouse as the Strategic Differentiator

In an era where leaders are breaking through the barriers by applying automation, cloud software, and analytics to the problem, the rest are struggling to keep their heads above water.

Focused on lowering the amount of time, cost, and labor that it takes to get an order out the door within ever-shrinking time constraints, companies use warehouses not as just storage facilities filled with racks, but as strategic differentiators.

By connecting all points within the warehouse—and then aligning those points with the outside world—manufacturers, distributors, and retailers are overcoming key pain points that include (but aren’t limited to):

- The persistent and unpredictable trade wars. Companies are literally going out of business because their current technology solutions can’t keep up with the constantly changing tariff situation.

- Keeping up with delivery demands. Both B2C and B2B customers want their orders as quickly as possible—usually within a day or two. The company that falls behind risks losing market share to a competitor that’s literally one mouse click or screen tap away.

- Managing high return volume. Driven by e-commerce, return volume will cost $550

billion this year, up from $381 billion in 2018. As this number continues to mount,

companies need cloud technology solutions that help them efficiently manage this aspect of their business. - Poor inventory management. In the absence of real-time information accessible on a mobile device, employees and customers are left to “guess” at the accuracy of their inventory data.

- Systems that don’t integrate. Built-in silos, older legacy systems weren’t designed to integrate well with other systems. A cloud WMS, on the other hand, can easily be connected to other operational systems, thus creating a complete smart warehouse or Industry 4.0 information loop.

- Inability to compete on a global scale. When a manufacturer or distributor starts doing

business on a global scale, it needs robust shipment planning and shipment cycle tools

that support these initiatives. - No robust data analytics to work from. Too many distributions and manufacturing operations rely on historical data to make forward-looking decisions. The problem is that if you’re always looking in the rear-view mirror, how can you see what lies in front of you?

Not as Simple as it Looks

As a discipline, warehousing looks simple enough on the surface: identify a product, pick it, package it, and ship it out the door. In reality, these operations are extremely complex animals that require good orchestration and deserve high levels of attention.

Add the complexities of same-day and next-day delivery, the rapid uptick in e-commerce, the demands of omnichannel fulfillment, and the Amazon Effect to the mix, and it’s clear why a cloud WMS has become a must-have for any successful operation.

Along with solving the pain points outlined above, cloud WMS also helps the smart warehouse or Industry 4.0 operation by:

- Being affordable. No Capex investment is required here, just a monthly subscription fee. Cloud WMS offers “out of the box” functionality that helps to immediately lower the total cost of ownership (TCO) for the software, with upgrades included in the monthly subscription.

- Not eating up internal IT resources. Because it runs in the cloud, there’s no need for a

dedicated IT team to monitor and maintain your WMS, nor will you need expensive

hardware or servers. - Getting up and running quickly. The system can usually be configured and branded

within a few weeks (the timeline may be longer for more complex operations). - Letting you focus on what you do best. Instead of worrying about running their WMS,

distributors can distribute goods, manufacturers can make great products, and retailers

can focus on serving their end customers. - Using devices that your employees already know (and love). With Foysonis’ cloud WMS, you can choose between iOS or Android, of which both are native to the application. Deep-six the green screens and the “F1” and “F2” keypunches and instead leverage the advanced user experience already available in today’s smartphones.

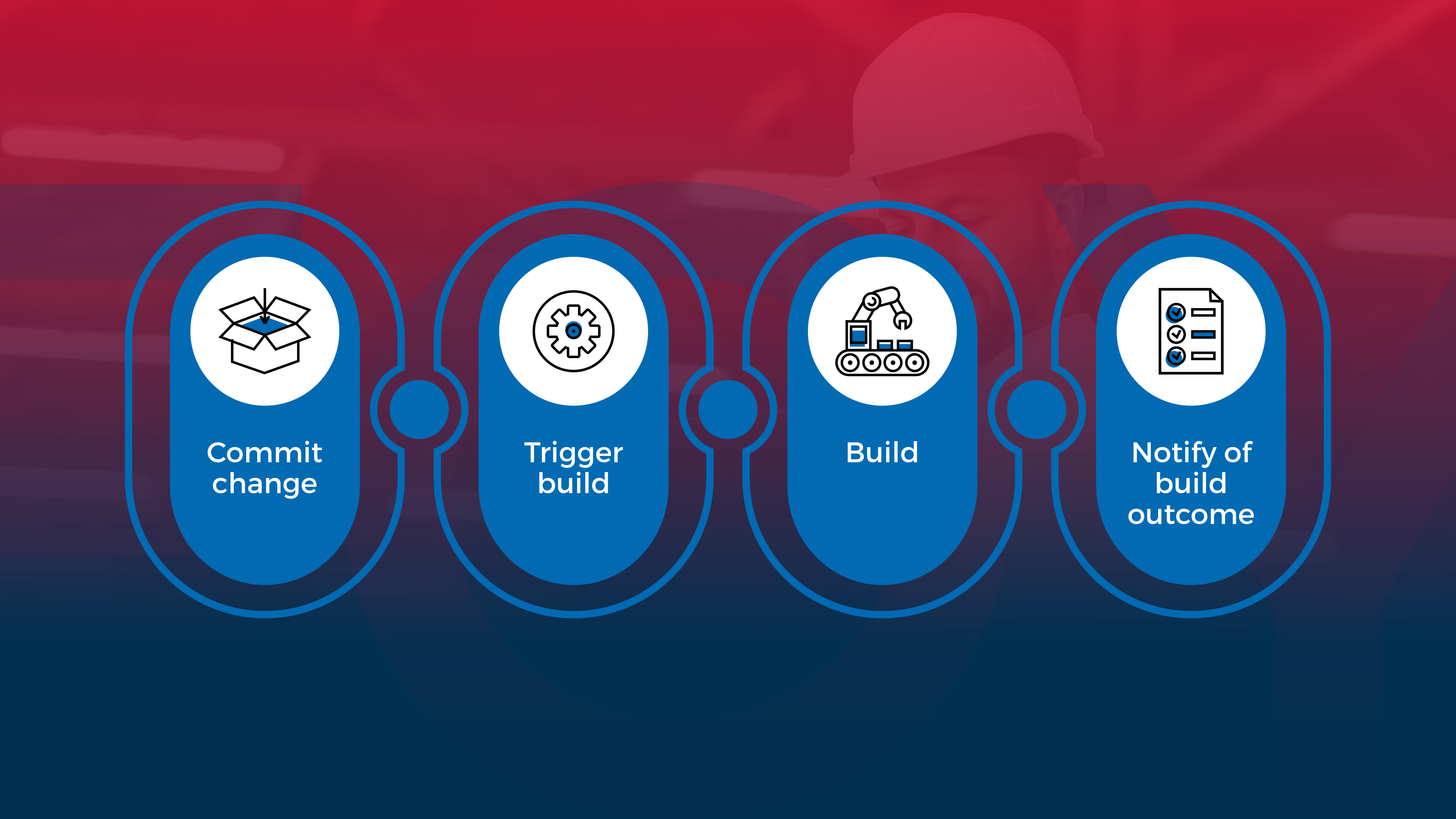

- Updating systems in real-time. With Foysonis’ API (application programming interface),

you can pull data from your cloud WMS and use it to update your systems in real-time.

Managing in the Face of Complexity

As more and more companies are impacted by the trade wars, labor shortages, geopolitical events, and other disruptive forces, the need for technology systems that can adapt quickly is growing exponentially. Add to this the complexities of e-commerce, omnichannel, and the labor shortage, the need for a full-featured WMS in the cloud becomes even clearer.

As the fourth industrial revolution continues to take shape, and as more companies invest in smart warehousing capabilities, demand for a robust, cloud-based technology that meets the demands of the modern facility will also continue to grow.

Unable to flex quickly, on-premise legacy systems will no longer be the answer for most companies. Knowing this, more organizations will look to cloud-based systems that enable high levels of flexibility and adaptation—all while providing a full suite of services that today’s competitive business environment demands.