Smart Warehousing

By , 18 September 2025 15:45

From Maps to Autopilot: Why Adaptive AI Is the Future of Supply Chains

By Ilango Veera, Founder of Foysonis

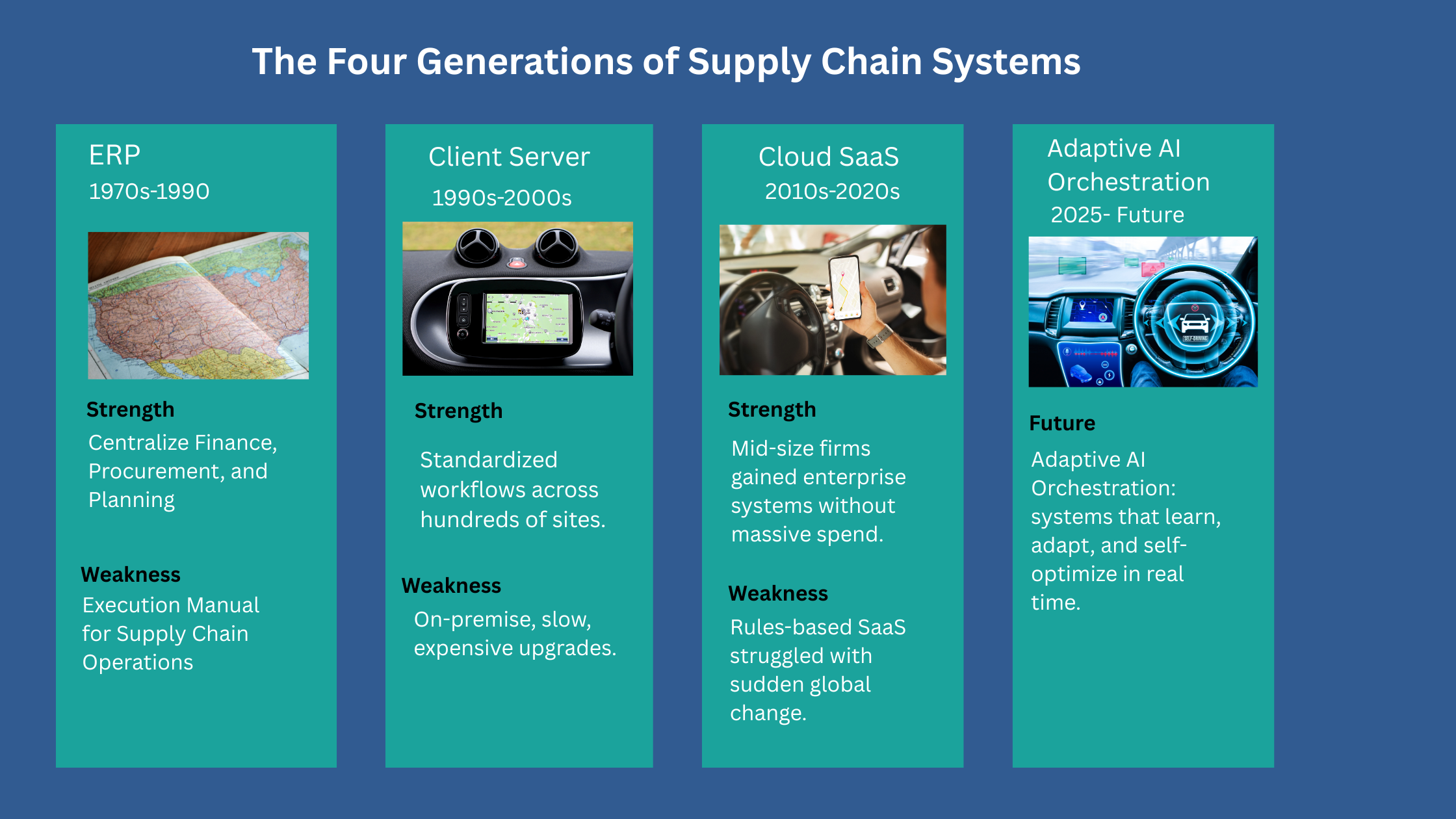

Every few decades, technology reshapes the way global commerce operates. In supply chains, three generations of software have transformed how companies plan, move, and manage goods. Each was a milestone — but each also carried a limitation.

ERP systems centralized, client-server WMS and TMS automated, and Cloud SaaS made logistics technology accessible at scale. Yet across all three waves, the underlying logic remained the same: static rules driving dynamic operations.

That model has reached its limit. Today’s supply chains stretch across continents, constantly exposed to shocks from extreme weather, labor shortages, cyberattacks, and shifting consumer demand. A system built on rules cannot keep up with a world defined by uncertainty.

The next generation is different. Adaptive AI Orchestration is not about making rules faster — it’s about replacing them with systems that learn, adapt, and improve continuously.

A Brief History of Supply Chain Technology

- ERP Era (1970s–1990s): SAP and Oracle created the first integrated backbones of enterprise IT. They provided a single source of truth for finance and procurement, but execution still relied on clipboards and manual workflows.

- Client-Server Era (1990s–2000s): Vendors like Manhattan Associates and JDA digitized execution. Warehouses gained barcode scanning, routing algorithms, and automated workflows. Yet implementations were costly, upgrades painful, and systems rigid.

- Cloud SaaS Era (2010s–2020s): Subscription-based platforms such as Manhattan Active, Oracle Cloud SCM, and newer saas startups made advanced supply chain tools widely available. Deployments were faster, updates continuous. But the logic was still rule-based — and rules break under stress.

Each era brought progress. But each also showed the limits of technology that executes rather than learns.

The Leap to Adaptive AI

At Foysonis, we believe the fourth generation has arrived: AI-first systems built for autonomy.

Our Helix WMS doesn’t just manage workflows — it orchestrates them, using a deep AI stack designed for resilience and continuous improvement:

- Reinforcement Learning agents that evolve picking, slotting, and routing strategies by learning directly from warehouse operations.

- Monte Carlo Tree Search (MCTS) to simulate thousands of disruption scenarios in real time, from weather events to sudden demand spikes.

- Graph Neural Networks (GNNs) that map and optimize the entire logistics ecosystem — modeling suppliers, carriers, warehouses, and customers as interconnected nodes.

- Digital twins that mirror real-world warehouses, enabling safe experimentation and continuous performance tuning without risking live orders.

- Retrieval-Augmented Copilots (RAG) that bring natural language interaction into supply chain management, allowing operators to configure processes and query performance in plain English.

This isn’t a patchwork of add-ons. It’s an architecture designed from the ground up for autonomy.

The Foysonis Vision: Technology and ROI

At Foysonis, our vision is to transform supply chains from static, reactive systems into living, adaptive networks. That vision isn’t just about technology — it’s about measurable business outcomes.

Consider the economics:

- Labor Efficiency: In a typical $1B distribution network, labor accounts for 50–60% of operating cost. By applying RL-powered picking and slotting, Helix WMS can reduce travel time by 15–20%. That translates into $8–12M in annual savings per DC.

- Inventory Optimization: Traditional systems carry excess “safety stock” to offset uncertainty. With AI-driven demand sensing and slotting, Helix can reduce carrying costs by 8–12%. For a mid-size company holding $300M in inventory, that’s $25–35M freed up annually.

- Throughput and Service Levels: AI orchestration allows warehouses to flex capacity in real time, reducing bottlenecks during peak demand. Customers that miss peak shipments lose sales — but a Helix deployment can recover 2–4% of top-line revenue during high-volume seasons. For a $2B retailer, that’s $40–80M in preserved revenue.

- Disruption Resilience: According to McKinsey, supply chain shocks now cost companies 6–10% of annual revenue. By simulating and rebalancing in advance, Helix turns disruptions into manageable events. For a Fortune 500 manufacturer, that can mean hundreds of millions in protected earnings every year.

These are not theoretical numbers. They’re the direct result of moving from rule-based automation to AI-native orchestration.

Why This Matters

The economics are clear. According to Gartner, enterprise software spending exceeded $900 billion in 2024, with supply chain platforms among the fastest-growing categories. Fortune 500 companies now spend more than $250 billion annually on IT, while mid-size firms dedicate a larger share of revenue than ever before.

But technology alone doesn’t guarantee resilience. What matters is adaptability. And adaptability requires systems that learn.

The Autonomous Era Has Begun

The first three generations gave us road maps, static GPS, and connected GPS. Each was progress, but each still depended on the driver.

Helix WMS represents the next leap: autonomous orchestration. A system that perceives, decides, and improves in real time. A system that grows stronger with every order processed. A system that delivers ROI not in years, but in quarters.

At Foysonis, our mission is clear: to usher in the autonomous era of supply chains. Not as a vision for tomorrow — but as a reality being built today.

Recent Posts

Billions Spent on Supply Chain Tech, Yet Warehouses Still Run on Yesterday’s Logic

3 Signs Your Warehouse Operations Are Ready for a Digital Upgrade